Assembly Solutions Tailored to Your Business Constraints

Every industrial project comes with specific constraints related to its use, operating environment and technical requirements.

MovNtec supports customers across a wide range of industries by applying an industrial analysis of needs based on product materials and functions.This approach enables us to deliver relevant industrial assembly solutions for diverse projects whenever industrial rigor, reliability and scalability are required.

Understanding Your Needs and Constraints Before Structuring Assembly

LMovNtec’s involvement in your industrialization project always begins with a thorough understanding of:

- the product’s functions;

- its operating environment;

- mechanical, electrical or thermal constraints;

- quality and durability requirements.

Based on these elements, our experts structure the assembly process, define methods and select materials and components suited to your industry.

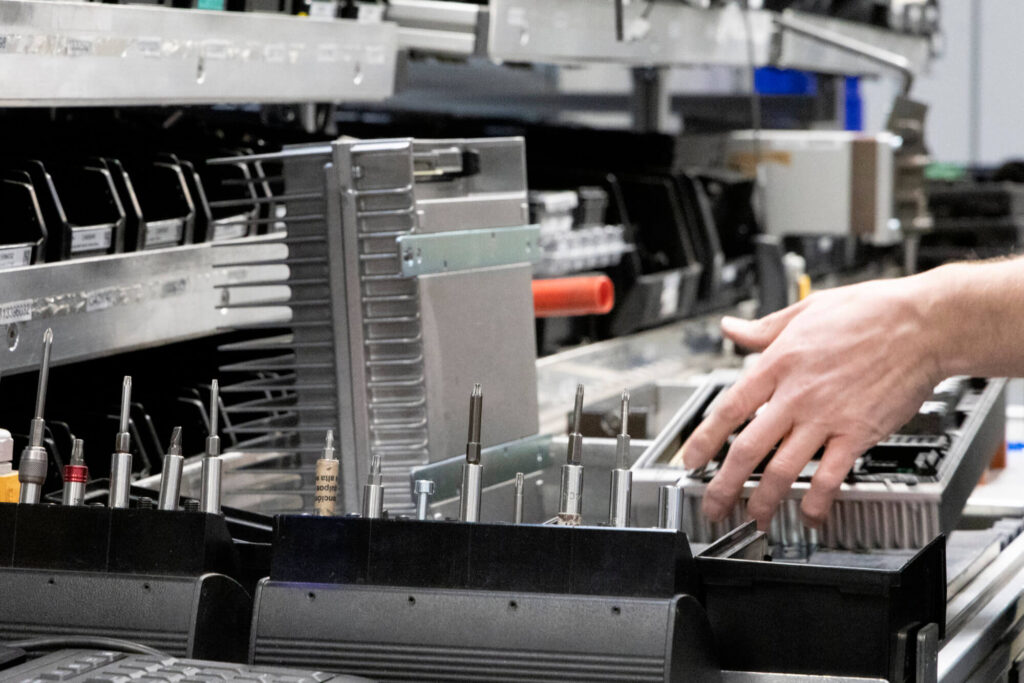

Materials Expertise Serving Industrial Assembly

Products assembled by MovNtec rely on a wide range of technical materials, selected according to their mechanical properties, resistance and final use.

This diversity requires a rigorous industrial approach to ensure assembly compatibility and final product quality.

Multi-Material Assemblies Aligned with Product Functions

Our teams work on assemblies integrating, in particular:

- metal parts requiring precision, robustness and long-term durability;

- plastic or composite components for weight reduction or insulation constraints;

- assemblies combining mechanics, electronics and functional interfaces.

The assembly of these heterogeneous materials relies on controlled processes that ensure operational repeatability and sub-assembly reliability.

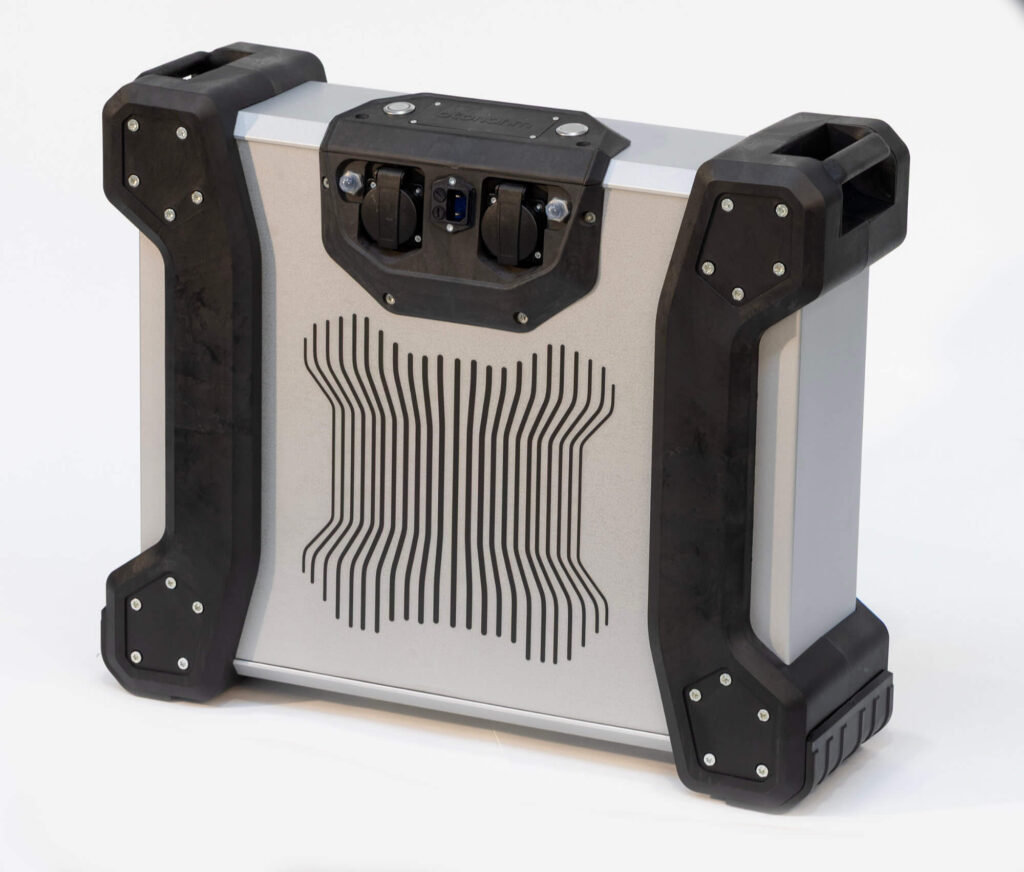

Processes Designed for Demanding Operating Environments

Products entrusted to MovNtec are intended to operate in a wide range of environments, sometimes under demanding conditions.

Our assembly processes are designed to meet requirements such as:

- resistance to mechanical stress;

- reliability under intensive use conditions;

- durability throughout the product lifecycle;

- compliance with strict functional requirements.

By integrating usage constraints directly into the assembly process, we secure product performance regardless of its final application.

Battery Assembly Line – A Dedicated Area of Expertise

L’The assembly of battery systems for electric and hybrid applications—whether for mobility or energy storage—is a specialized field subject to particularly stringent technical and safety requirements.

MovNtec has developed a dedicated battery assembly line capable of meeting the specific constraints of this sector:

- assembly of battery modules and packs in a controlled environment;

- integration of thermal management systems and electronics (BMS);

- compliance with electrical safety and impact resistance standards;

- full traceability of components and assembly processes.

This line supports a wide range of configurations, from pre-series to small and medium production runs, while managing the risks associated with lithium-ion cell handling and the integration of performance- and durability-critical components.

Shared Industrial Challenges Beyond Industry Sectors

While application fields may vary, the industrial challenges faced by our customers are often similar:

- securing product reliability before or during production ramp-up;

- structuring a repeatable and controlled assembly process;

- outsourcing production that has become complex or non-strategic;

- absorbing increased volumes without compromising quality.

MovNtec addresses these challenges by providing an industrial organization capable of adapting to the project’s maturity level and evolving over time.

Thanks to its expert teams and manufacturing facility in France, MovNtec can manage complex, multi-material technical assemblies and adapt its processes to product-specific constraints—from pre-series to full production ramp-up.