From Prototype to Industrial Production: Structuring Pre-Series Assembly

The transition from a functional prototype to serial production is a critical phase in a product’s industrial lifecycle. Between technical validation of the concept and production ramp-up, an intermediate step is essential: pre-series production. This phase makes it possible to structure assembly operations, secure technical choices and prepare the conditions for repeatable production.

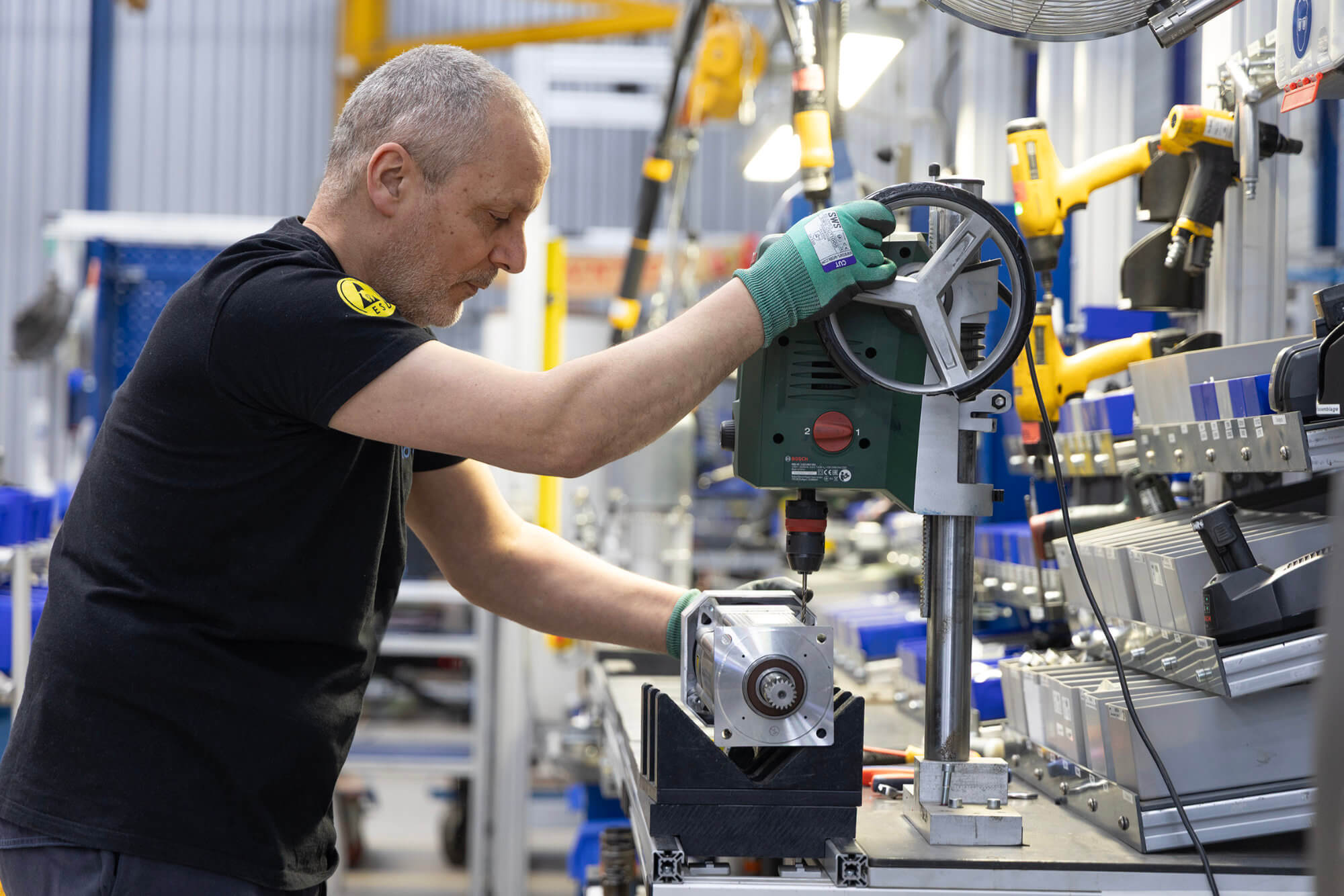

MovNtec supports this industrial transition starting from an existing prototype. Our role is to transform a functionally validated product into an industrialized assembly by addressing four key challenges: process reliability, operational repeatability, industrial scalability and cost control. We do not intervene upstream in product design. Our expertise focuses exclusively on the industrialization of assembly.

Are you looking to industrialize your pre-series production?

Industrial Challenges in the Transition from Prototype to Production

LThe prototype is the starting point of our intervention—not the end goal. A technically validated product is not automatically suited for industrial-scale production. Significant gaps exist between a functional prototype and a product that can be assembled reliably in series.

These gaps typically involve:

- adapting assembly operations to production and volume constraints;

- selecting components based on availability, cost and industrial compliance;

- defining repeatable and controlled assembly methods;

- identifying critical points that may impact quality or production rate.

Without an intermediate industrialization phase, industrial risks increase significantly: quality drift, non-conformance costs and extended time-to-market. Moving directly from prototype to serial production without a structured methodology often leads to major difficulties during ramp-up.

Pre-Series Production – A Key Step Between Prototype and Serial Manufacturing

La pré-série représente la phase de transition structurée entre le prototype et la producPre-series production is the structured transition phase between prototype and serial production. It involves manufacturing a limited number of units under conditions close to final production, in order to validate and optimize the assembly process.

The objectives of pre-series production include:

- testing assembly under real production conditions;

- securing technical choices related to components, tooling and assembly sequences;

- preparing production ramp-up by identifying necessary adjustments before serial production;

- validating operation repeatability and assembled product conformity.

It is important to distinguish between two fundamentally different approaches:

- Product prototyping: design and functional validation of a concept;

- Industrial assembly prototyping: structuring the assembly process based on an existing product.

MovNtec operates exclusively in the second area. We do not design products—we industrialize their assembly. Our expertise lies in transforming a validated prototype into a reliable and scalable assembly process.

Would you like to structure the transition of your prototype to production?

How Does MovNtec Support Prototype Industrialization?

MovNtec intervenes once a functional prototype already exists. Our support focuses on assembly industrialization by structuring operations and organizing flows to enable controlled serial production.

Industrial Analysis of the Existing Prototype

The first step consists of an industrial assessment of the product. Our methods teams analyze the prototype from an industrial assembly perspective, identifying:

- industrialization blockers: hard-to-source components, complex assembly sequences, tooling constraints;

- critical characteristics to control in order to ensure assembled product conformity;

- optimization opportunities to reduce costs or improve repeatability.

This analysis covers the entire product: components, sub-assemblies, assembly sequences and functional interfaces. The objective is to anticipate industrial challenges before production begins.

Assembly Industrialization

Based on the industrial analysis, MovNtec structures the assembly process:

- definition of assembly routings: detailed description of operations, sequencing and parameters;

- structuring of workstations: flow organization, resource sizing and allocation;

- selection of operating methods: assembly techniques adapted to volumes and product constraints;

- integration of quality and repeatability principles: inspections, conformity criteria and traceability.

This industrialization phase transforms the prototype into a structured assembly process ready for gradual ramp-up. The product remains technically identical, but the way it is produced becomes controlled, repeatable and scalable.