Industrial Assembly: A Complete Solution to Manufacture Your Technical Parts and Sub-Assemblies

Outsourcing industrial assembly is no longer solely a capacity issue. Today, it is a strategic industrial lever to secure production, control quality and support product evolution over time.

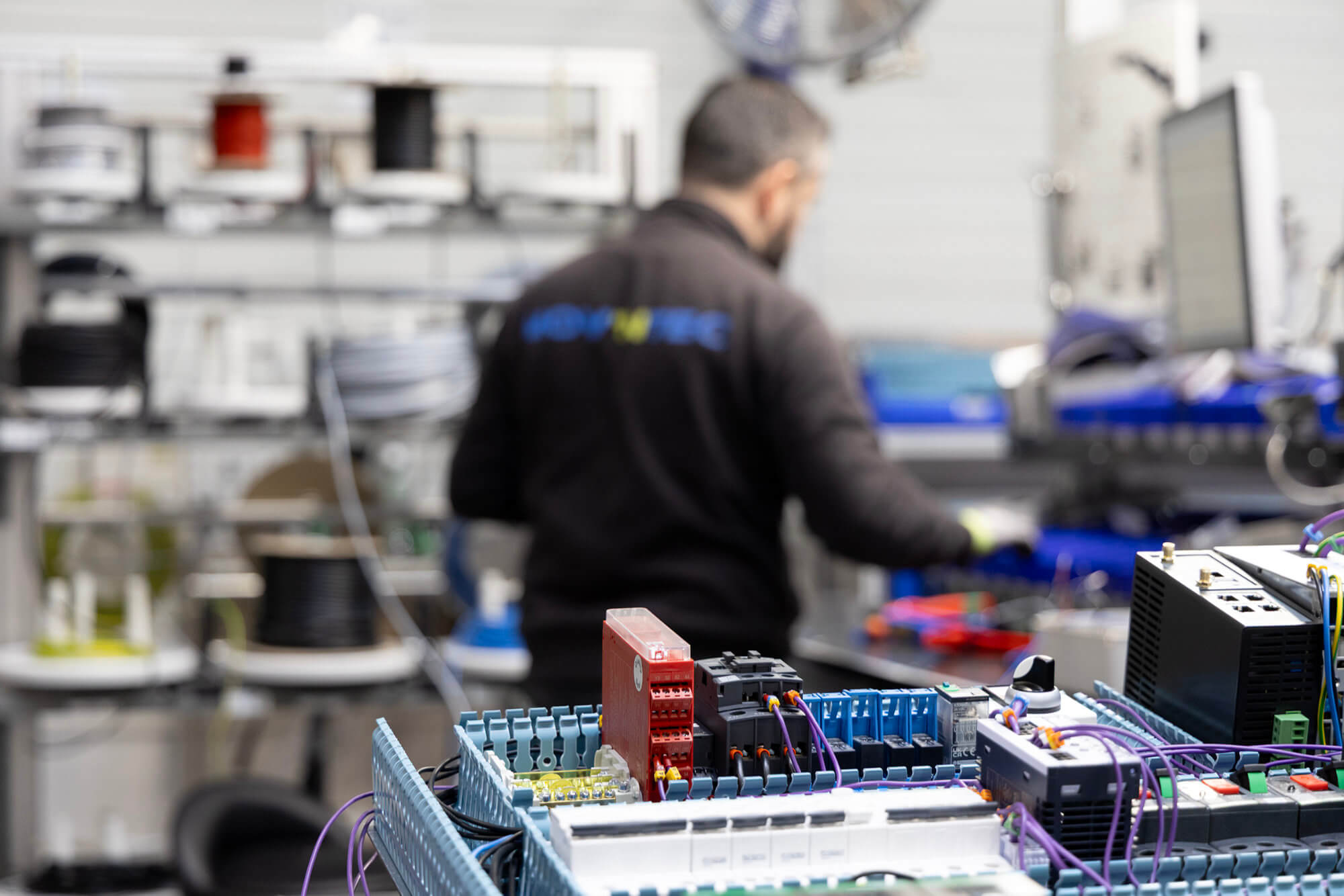

At MovNtec, we support companies with the assembly of industrial parts and technical sub-assemblies by offering a complete solution, from component sourcing to fully assembled, inspected and delivery-ready products.

Our approach is designed for high value-added projects combining mechanical, electromechanical and electronic elements, for small and medium production runs, within a structured industrial framework based in France.

Do you have an industrial assembly project or a production challenge to outsource?

Industrial Parts Assembly and Technical Sub-Assemblies

Outsourcing industrial assembly is not simply about delegating execution. It means entrusting an industrial partner with the responsibility to structure, secure and sustain a production process aligned with technical constraints, volumes and performance objectives.

At MovNtec, industrial parts assembly is part of a global approach designed to ensure reliability, repeatability and scalability of production.

Prototyping

Technical validation of your concepts. We structure assembly from the prototype phase to secure the transition to mass production.

Industrialization

Definition of production processes and flow organization. We transform your product into a reliable, scalable, and high-performance industrial solution.

Supply & purchasing

Component sourcing and procurement. Supplier flow management to secure lead times and ensure availability.

Production & testing

Technical assembly with integrated quality controls. Functional testing and full traceability guaranteed at every manufacturing stage.

Logistics

Packaging, storage, and shipping of your products. End-to-end management ensuring continuity of your production chain.

After-sales service

After-sales support and spare parts management. Industrial expertise extended beyond the mass production phase.

End-to-End Industrial Assembly Management

As a global industrial assembly solution provider, MovNtec supports all critical stages of the project, adapting its level of involvement to each customer’s context:

- component purchasing and sourcing, aligned with technical constraints and volumes;

- definition of assembly processes and work instructions;

- organization of workstations and production flows;

- assembly of industrial technical parts;

- in-process and end-of-line quality inspections and functional testing;

- packaging, logistics and shipping;

- after-sales service and spare parts management, as required.

This end-to-end approach reduces interfaces, limits industrial risks and secures long-term production.

High Value-Added Technical Sub-Assembly

Our teams assemble industrial components and mechanical, electromechanical or electronic sub-assemblies, integrating functional, usage and quality constraints from the earliest project stages.

We work in particular on:

- industrial metal sub-assemblies;

- complex industrial parts sub-assemblies;

- products combining mechanics, wiring, electronics and functional interfaces.

Each project follows a structured methodology designed to ensure:

- repeatability of operations;

- control of tolerances and fits;

- full traceability of assemblies;

- compliance of the final product with defined requirements.

An Industrial Assembly Process Adapted to Each Project

MovNtec’s ability to adapt to a product’s level of industrial maturity is a key component of our industrial assembly offering.

We support projects:

- during pre-series or prototyping phases, to secure industrial choices and structure initial assembly processes;

- during production ramp-up, with progressive adaptation of equipment, methods and organization;

- as part of outsourcing or production transfer for already industrialized products.

Processes evolve according to volumes, quality constraints and performance objectives. This progressive approach enables a transition from flexible organization to more standardized, or even partially automated, processes—while maintaining a high level of control.

Whether your product is in pre-series or already industrialized, assembly organization is a critical success factor.

Mechanical, Electronic and Pre-Series Assembly – Complementary Expertise

Industrial assembly at MovNtec is built on complementary areas of expertise, mobilized according to product type and complexity:

- Mechanical assembly: integration of parts and sub-assemblies, adjustments, screwing, bonding and functional mechanical operations;

- Electronic assembly: integration of PCBs, wiring harnesses and electronic components, with associated inspections and testing;

- Prototyping and pre-series: support in structuring processes between prototype and serial production to secure assembly prior to volume ramp-up.

These combined capabilities allow us to handle complete, technical and scalable products while maintaining overall industrial consistency.

A Manufacturing Site in France Dedicated to Your Production

As an industrial assembly subcontractor based in France, MovNtec relies on a production site capable of supporting projects with varying volumes and technical complexity.

This location enables:

- close operational collaboration with customer teams;

- greater responsiveness during project and production phases;

- control of lead times and quality standards;

- rapid adaptation of industrial resources.

We support regional industrial component assembly projects through long-term partnerships focused on continuous improvement and performance optimization.